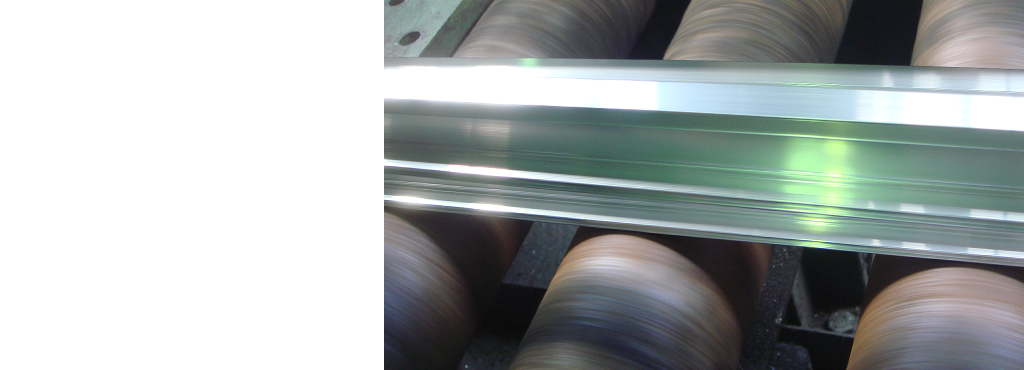

Needlefelts

manufactured from high temperature and high wear resistant fibers like Zylon, Kevlar, Golden Brown, Twaron, Nomex and Polyester solve handling and transport demands in the aluminum extrusion process.

SEE MORE

Separation & Filtration

Separation & Filtration highly efficient hydraulic and lube oil filter elements or cartridges, recycle them after use.

SEE MORE

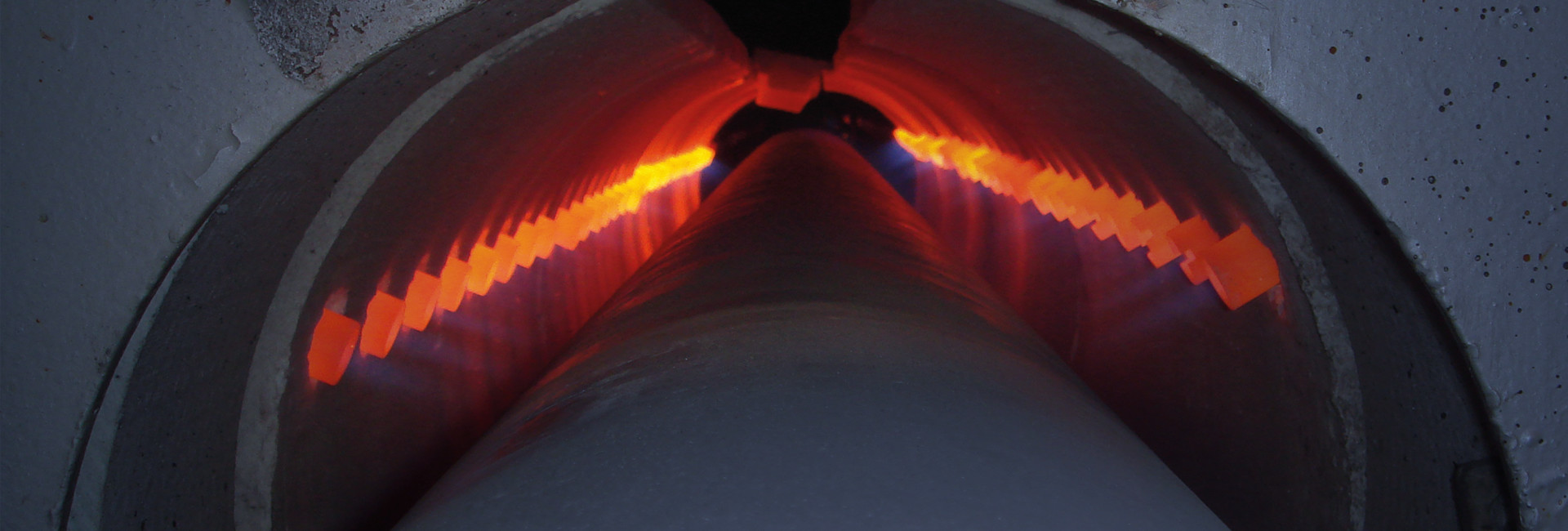

Refractory

Refractory Ceramic parts for billet ovens in different qualities. For high temperature shock resistance we advise to use our Quartz quality.

SEE MORE

Aluminum Extrusion Equipment Brokers

Aluminum Extrusion Equipment Brokers ECOFILL beeing active in the global Aluminium Extrusion Industry for decades especially with high- performance Needle felt products. Manufactured in our own production facilities in The Netherlands.

SEE MOREEcofill International B.V. has evolved from a supplier of a small range of specialized products to a full service partner for the aluminum extrusion industries around the globe.

Here you can learn about our products and services, visit some of our business partners or be entertained by a range of short movies, showing the in’s and outs of aluminum plants around the globe. If you have a specific problem and can’t find the answer on our website, please feel free to contact us. Our broad knowledge and experience in the field enables us to find a fitting solution for most industrial problems.

Products

Ecofill International manufactures needlefelts made out of typical high temperature and high wear resistant fibers like i.e. Zylon, Kevlar, Golden Brown, Twaron, Nomex, Conex and Polyester for all handling and transport solutions in the aluminum extrusion process.

Services

Ecofill has a team of skilled engineers and craftsmen ready to implement our products, help you out when you need an extra pair of hands or perform various other functions around your company.

Help Centre

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The Capture Total

ECOFILL power felts are the cosmetic for Aluminum Extrusions

-

Preventing scratches and dents on your profiles

-

Ultra durable and long lasting

-

Manufactured fl awless to perfection

-

Temperature ranges up to 650C

HONESTY Needle felt based Cosmetics for Aluminum Extrusions

All ECOFILL / HONESTY Needle felt Roller sleeves or Roller covers are completely seamless, round needled with or without resin impregnation, comprising an inside diameter tolerance of -0+0.15 mm for a perfect, easy to install fit.

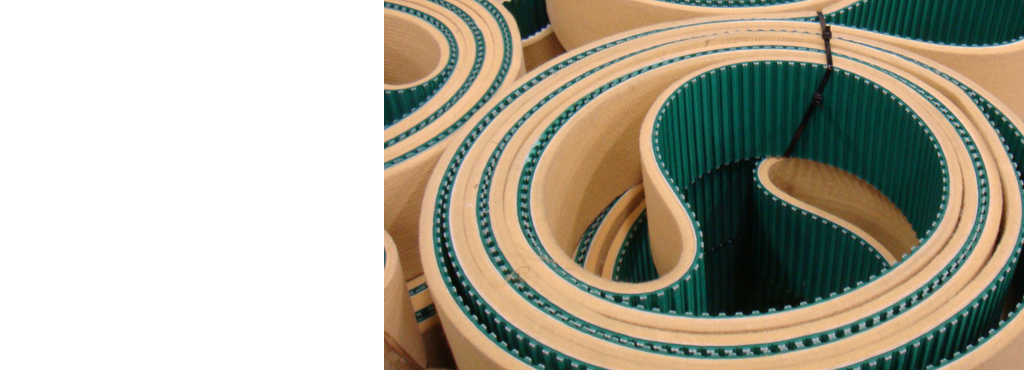

Main timing belt advantages

-

Virtually no elongations/stretching due to wear.

-

No need for tensioning devices.

-

Energy savings.

-

Reduced cost associated with downtime on top of lost productivity.

-

Precision registration and timing with no loss of high torque carrying capability.