ECOFILL’s extended fiber Range

Next to the commonly used fibers like PBO-Zylon, Kevlar, Nomex, PPS and Polyester, ECOFILL has introduced new High performance synthetical fibers for the aluminum extrusion industry; i.e. Golden Brown and Silon Australian Gold, providing a more economic and wider spread of felt products for specific customer requests and various high demanding applications. (High temperature and high wear resistant T600 upto T650).

Impregnation:

All ECOFILL/HONESTY Needle felt products are available with resin impregnation, not leaving stains on hot extruded aluminum profiles! The resin impregnation enhances the durability of the roller sleeves, belts, pads and makes it more stiff. The hardness of the roller sleeve can be adjusted by the concentration of the resin together with the amount of resin treatment cycles of the felt products. Next to a higher durability another advantage of resin impregnation is that aluminum swarf and or dirt does not stick into the felt.

Specialties:

Resin impregnation is the most common after treatment known in the industry; but ECOFILL looks beyond this point and also offers linished resin impregnated roller covers and on top cryogenic treated Needle felt rollers for an outside diameter tolerance of +/- 0.05 mm / Meter roller length!

Short delivery times

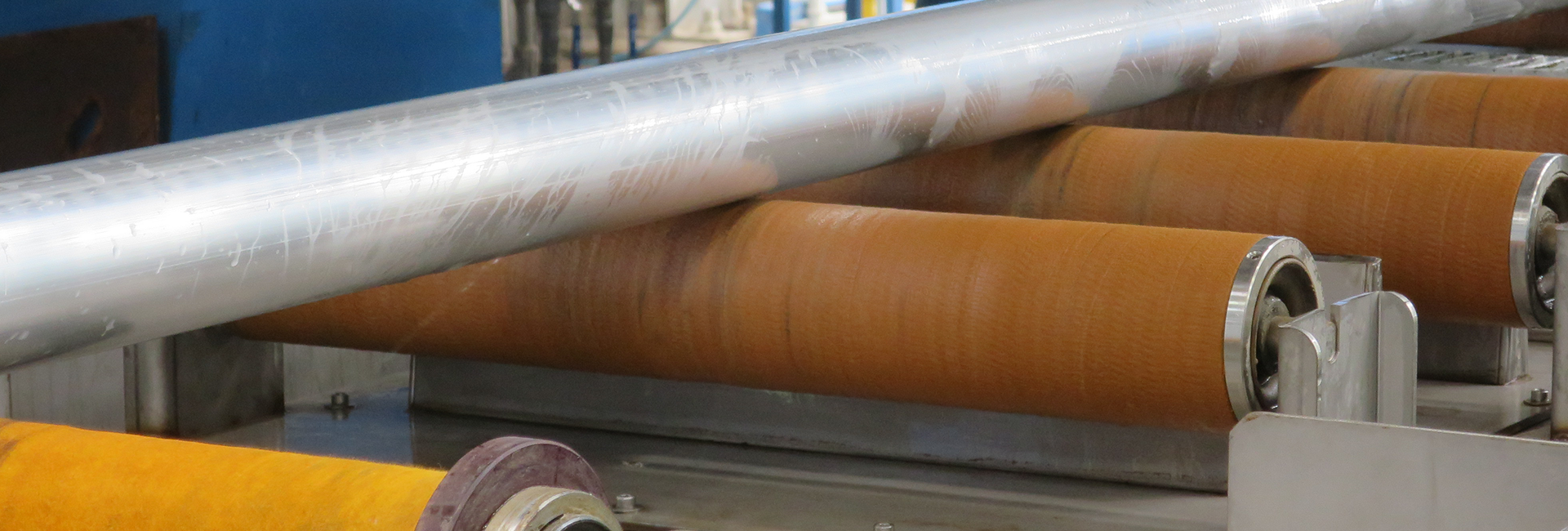

As we are running roller covers and belts on multiple needle looms most of the time we are able to comply with very short delivery times even on a global scale.

HONESTY Needle felt based Cosmetics for Aluminum Extrusions

All ECOFILL / HONESTY Needle felt Roller sleeves or Roller covers are completely seamless, round needled with or without resin impregnation, comprising an inside diameter tolerance of -0+0.15 mm for a perfect, easy to install fit.

Roller sleeves standard range

Full PBO / Zylon roller sleeve.

- Temperature resistance up to peaks of 1200 F / 650 C

- Really seamless and endless

- Round needled

- Smooth homogenious felt surface (no woven patterns)

- High pore volume without any affinity to stick on the extruded aluminum profiles.

Special resin impregnations or hardening available for all roller cover dimensions.

Application area: initial zone, run out and pick-up

Hybrid PBO / Zylon roller sleeve.

- Temperature resistance up to peaks of 1200 F / 650 C

- Really seamless and endless

- Round needled

- Smooth homogenious felt surface (no woven patterns)

- High pore volume without any affinity to stick on the extruded aluminum profiles.

Special resin impregnations or hardening available for all roller cover dimensions.

Application area: initial zone, run out and pick-up

Material: Top layer: PBO/ Zylon, Bottom layer: 50/50 mix PAR/PBO

Maxi Top

Hybrid PBO / Zylon roller sleeve.

- Temperature resistance up to peaks of 1200 F / 650 C

- Really seamless and endless

- Round needled

- Smooth homogenious felt surface (no woven patterns)

- High pore volume without any affinity to stick on the extruded aluminum profiles.

Special resin impregnations or hardening available for all roller cover dimensions.

Application area: initial zone, run out and pick-up

Material: Top layer: PBO/ Zylon, Bottom layer: 50/50 mix PAR/PBO

Honesty Golden Brown

- Temperature resistance up to peaks of 1020 F / 550 C

- Really seamless and endless

- Round needled

- Smooth homogenious felt surface (no woven patterns)

- High pore volume without any affinity to stick on the extruded aluminum profiles.

Special resin impregnations or hardening available for all roller cover dimensions.

Application area: initial zone, run out and pick-up; especially suitable for your waterquench or other moist environments.

Maxi Yellow

- Temperature resistance up to peaks of 1020 F / 550 C

- Really seamless and endless

- Round needled

- Smooth homogenious felt surface (no woven patterns)

- High pore volume without any affinity to stick on the extruded aluminum profiles.

Special resin impregnations or hardening available for all roller cover dimensions.

Application area: run out, pick-up cooling zones

Material: 100% PARA-ARAMID (Kevlar / Twaron)

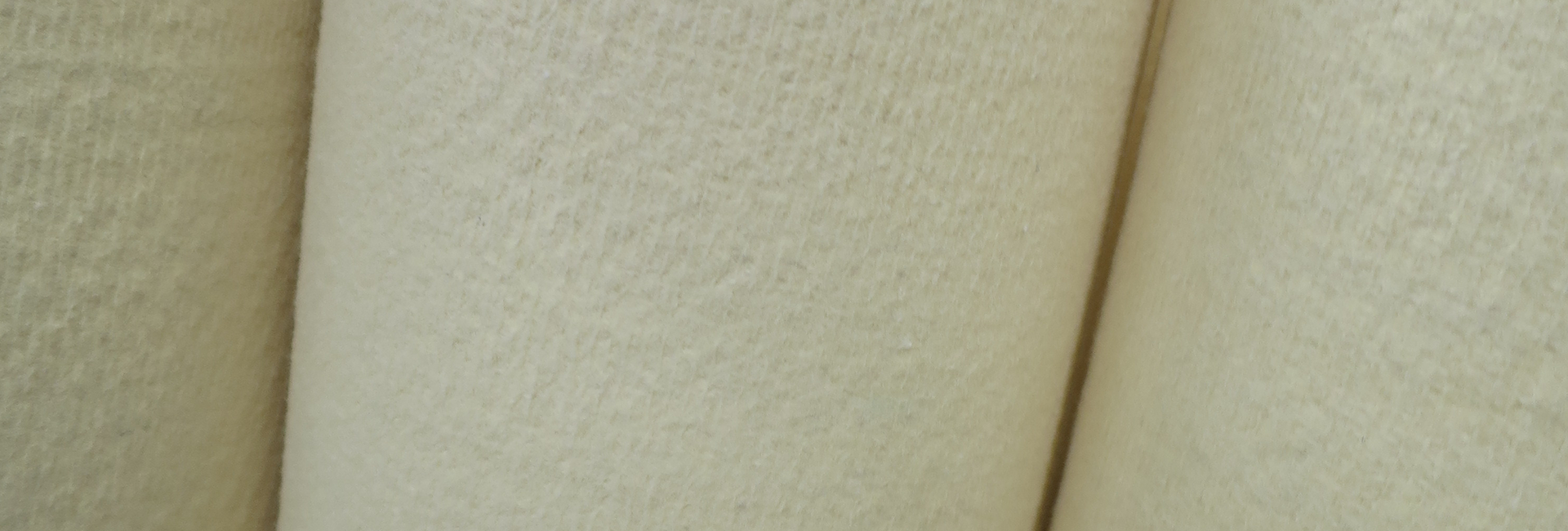

Maxi White Nomex Meta ARAMID

- Temperature resistance up to peaks of 518 F / 270 C

- Really seamless and endless

- Round needled

- Smooth homogenious felt surface (no woven patterns)

- High pore volume without any affinity to stick on the extruded aluminum profiles.

Special resin impregnations or hardening available for all roller cover dimensions.

Application area: transfer, stretching and spacers.

Maxi White Polyesther

- Temperature resistance up to peaks of 428 F / 220 C

- Really seamless and endless

- Round needled

- Smooth homogenious felt surface (no woven patterns)

- High pore volume without any affinity to stick on the extruded aluminum profiles.

Special resin impregnations or hardening available for all roller cover dimensions.

Application area: transfer, stretching and finishing saw.

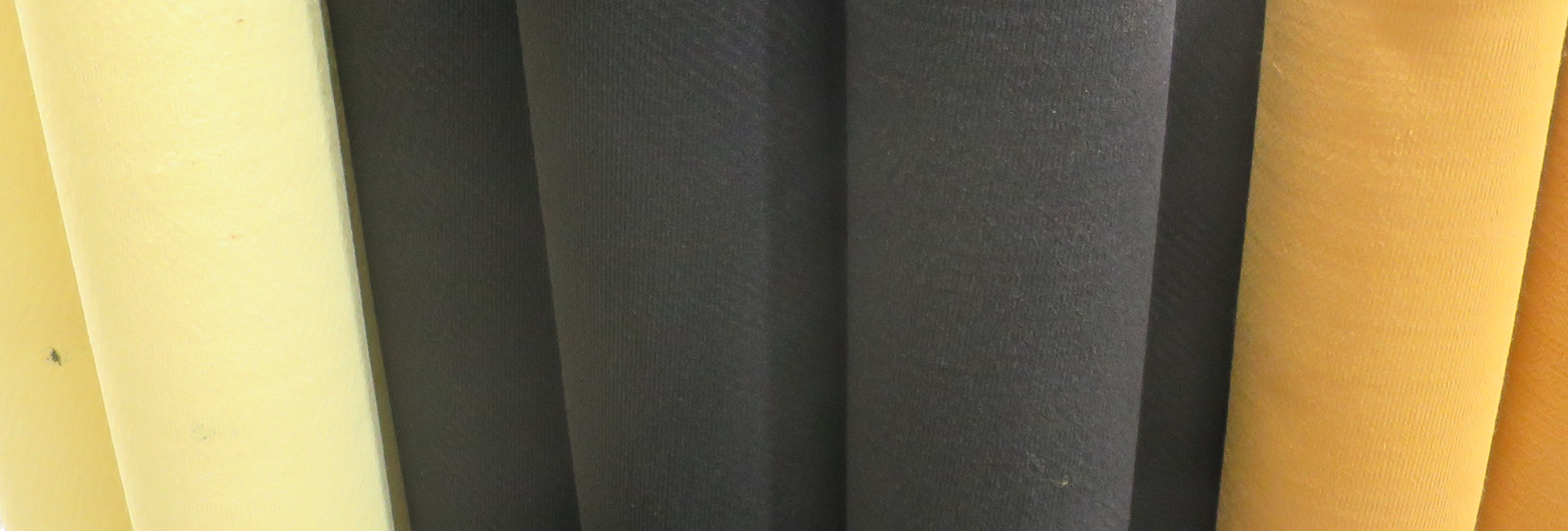

Maxi Black Polyesther

- Temperature resistance up to peaks of 428 F / 220 C

- Really seamless and endless

- Round needled

- Smooth homogenious felt surface (no woven patterns)

- High pore volume without any affinity to stick on the extruded aluminum profiles.

Special resin impregnations or hardening available for all roller cover dimensions.

Application area: transfer, stretching and finishing saw.

Features:

-

Roller covers manufactured in Zoeterwoude / The Netherlands for high temperature (T650) application down to rubber / Synthetic or plastics Rollers for low temperature ranges from 240C down to -10C.

-

Extremely smooth & homogenious felt surface

-

Optimal thermal insulation properties

-

Antistatic optional

-

Wide product range for individual systems

-

Different wall thicknesses (3.5 up to 13 mm) for most common ID’s

-

Special resin treatment for heavy presses

-

Round needled, seamless