The best timing belts

Simply maintaining ECOFILL’s reputation for producing the best (timing) belts for Aluminum Extrusions in the world is only part of the story.

ECOFILL has created a ‘new generation’ of timing belts that can withstand just about anything. Belts for highly abrasive, extreme hot Aluminum profiles. ECOFILL belts can handle it all!

All ECOFILL products have been tested to the limit ensuring that our conveyor belts perform exactly as they are designed to do.

The modern Aluminum extrusion industry demands ever-increasing standards of safety, quality, productivity and cost effectiveness.

Value for money

ECOFILL conveyor belts provide outstanding value for money because of their superior life-expectancy, excellent resistance to heat, abrasion, and leaving no marks or dents on the extruded profiles. ECOFILL Conveyor Belting has an outstanding track record of product innovation and development. We are extremely proud of the fact that our products have become the benchmark for the global Aluminum extrusion industry.

ECOFILL Conveyor Belting has developed a wide variety of CONVEYOR BELTS over the years to meet these demands in every stage of the extrusion process.

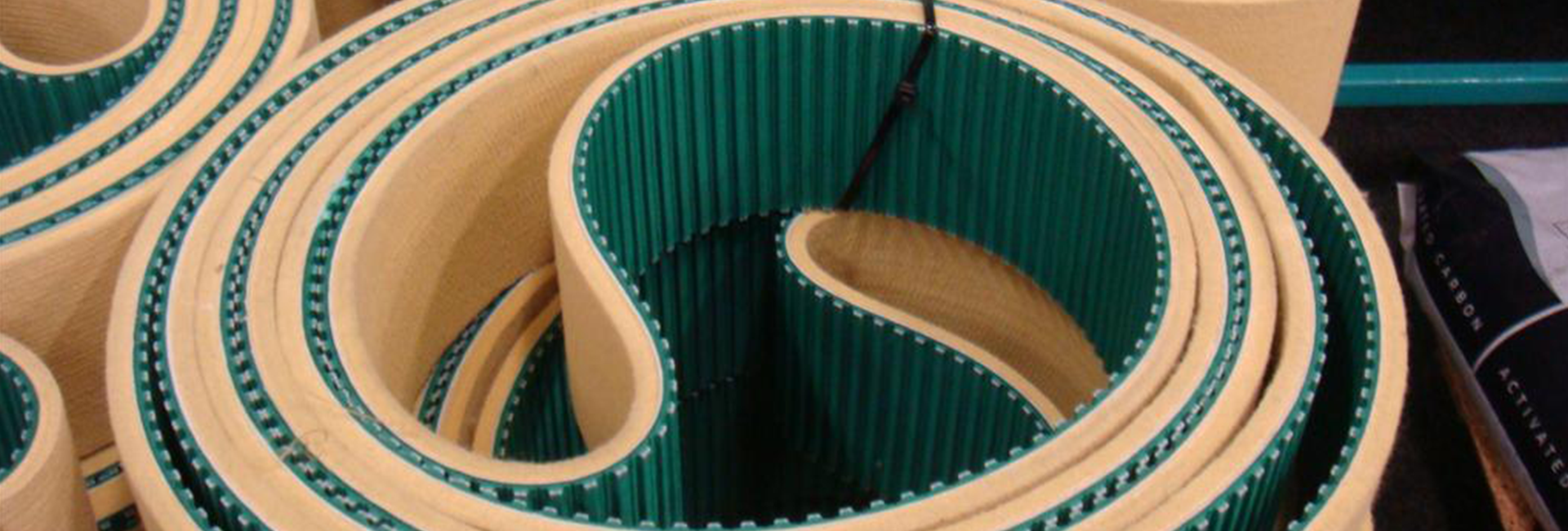

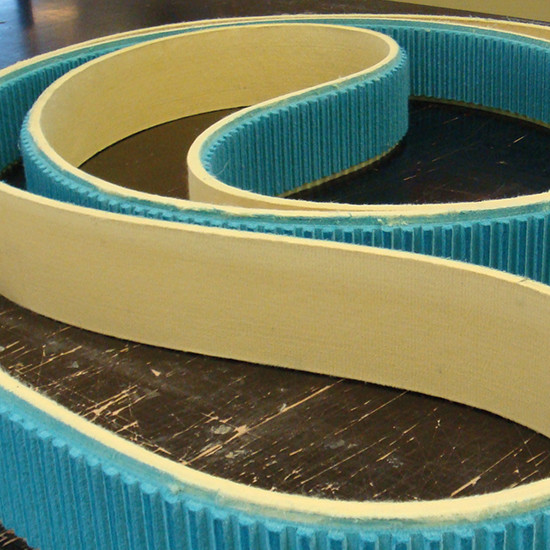

Timing Belts range

Timing Belts.

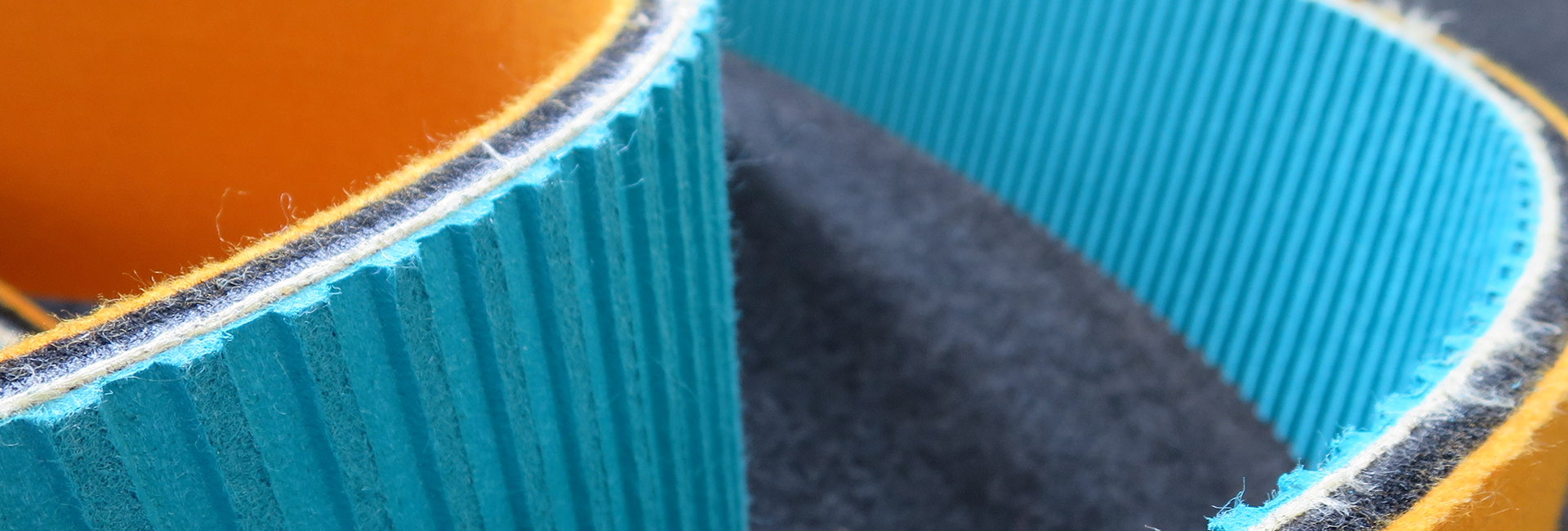

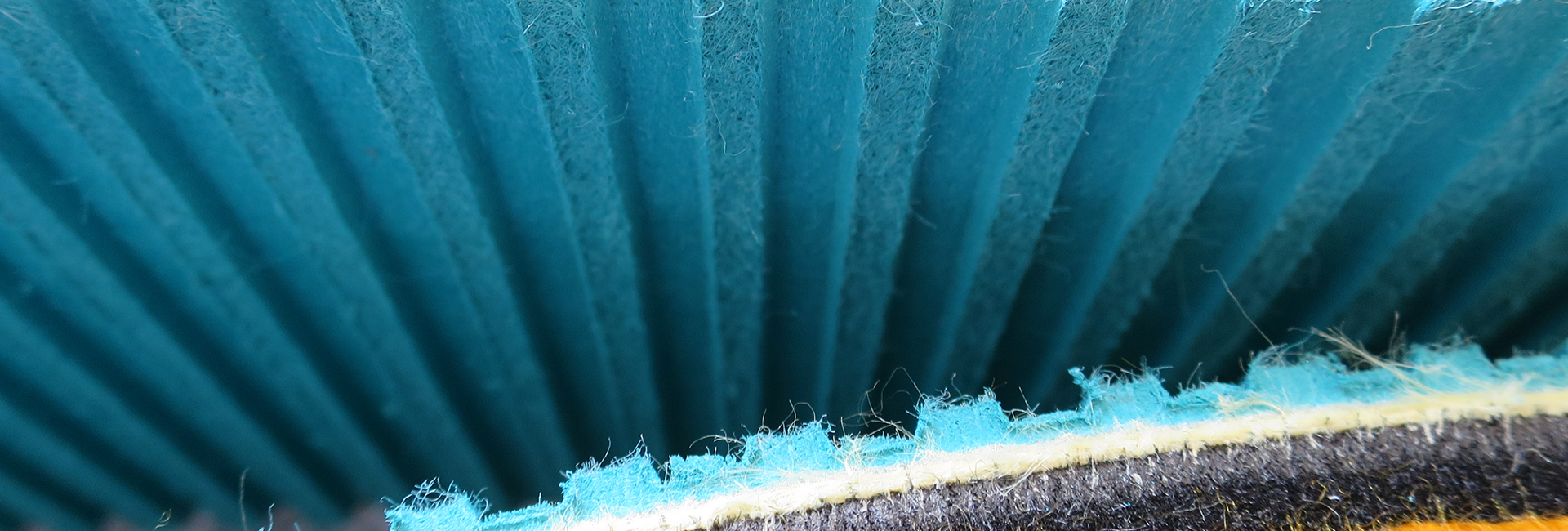

Ecofill has developed a unique way of needle punching bi-directional Endless Timing Belts. Ecofill timing belts:

- are completely endless, NO joints (unless you want them).

- do NOT contain any polyester material.

- will stretch less than 0.1%.

- have hard edges on the driving sides to prevent the belt from getting astray.

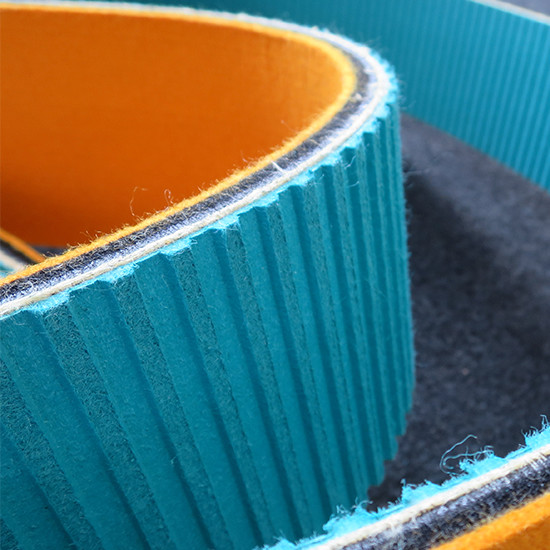

- have a special backing that gives up to 40% more grip on the driving pulleys than other belts and 30% less friction on the arms.

Timing Belts.

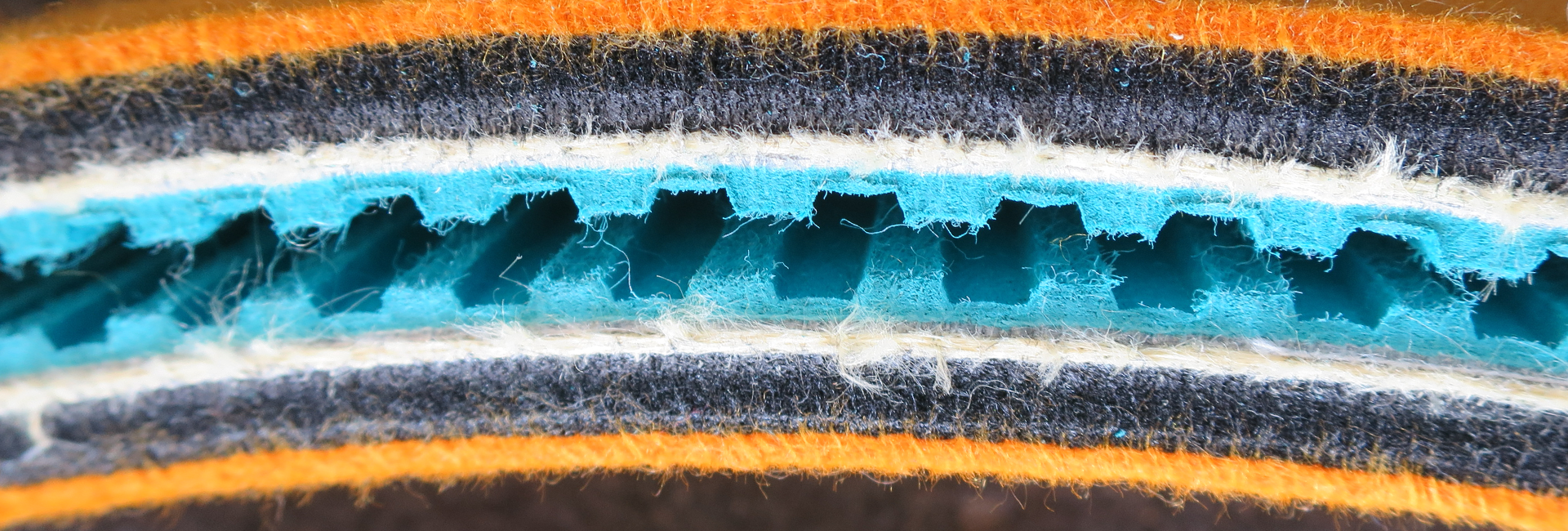

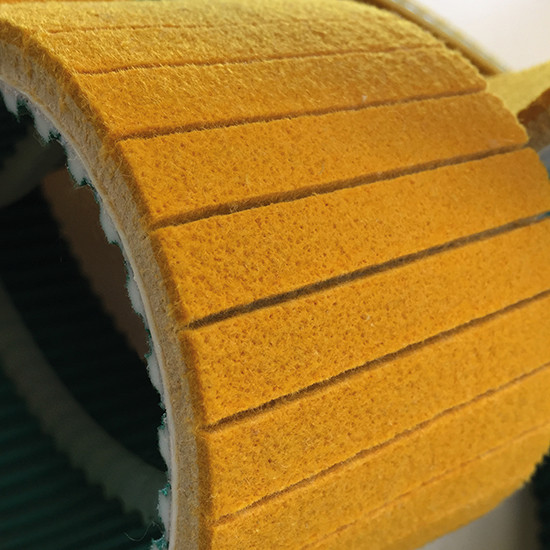

- Top surface : Felt material / hot vulcanized

- Carrier material: Termoplastic polyurethane

- For industrial applications

- Different teeth available from T5 up to AT20

- Various tracking guides available

Main timing belt advantages:

-

Virtually no elongations/stretching due to wear.

-

No need for tensioning devices.

-

Energy savings.

-

Reduced cost associated with downtime on top of lost productivity.

-

Precision registration and timing with no loss of high torque carrying capability.

Styles of ECOFILL timing belts:

-

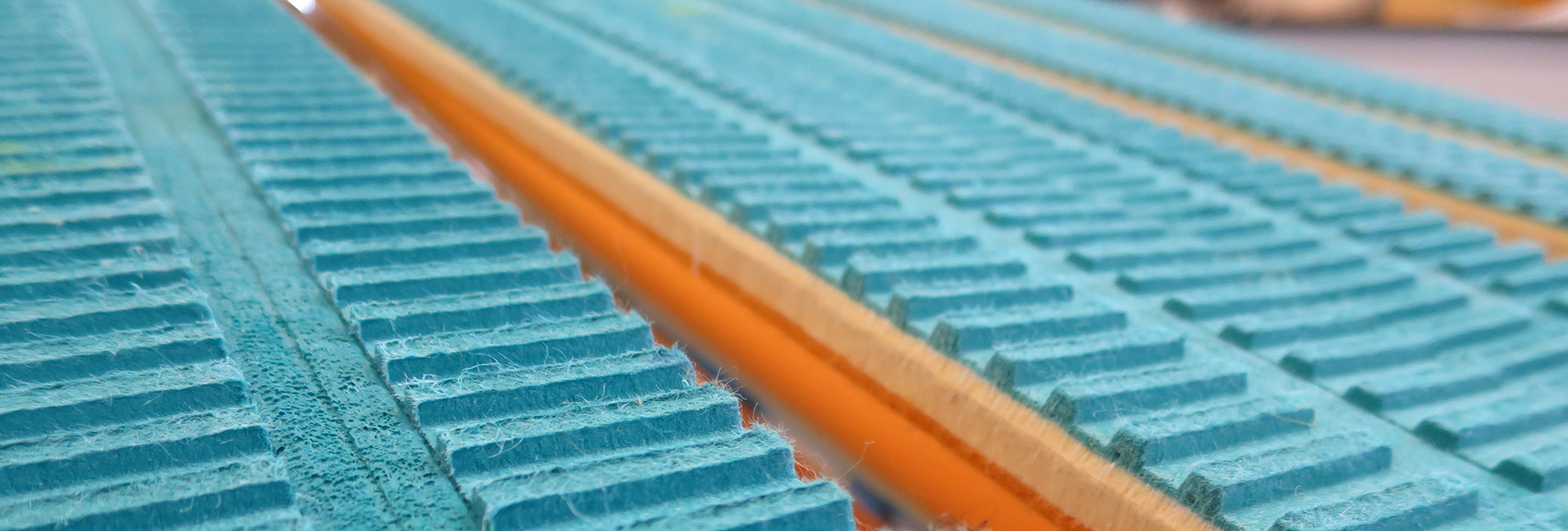

Regular timing belt with a seam or joint at 45 degrees

-

Regular timing belt with a joint and additional CROSS-CUTT on the top surface

-

Superior timing belt; truly endless; no joint or seam; no vulcanization; no glue but made out of 100% Needle felt